CADskills: The new era of medical implants

Text: Arne Adriaenssens | Photos: CADskills

I n the field of implants, only the best suffices. The difference between a superior or inferior one can, in the end, change your life entirely – for better or for worse. Belgian medical implant pioneer CADskills has developed high-quality, custom-printed medical devices which are taking the world by storm. Because not only does its CAD/CAM creations fit the patients like a glove, they also speed up the surgery time significantly and reduce the chance of complications.

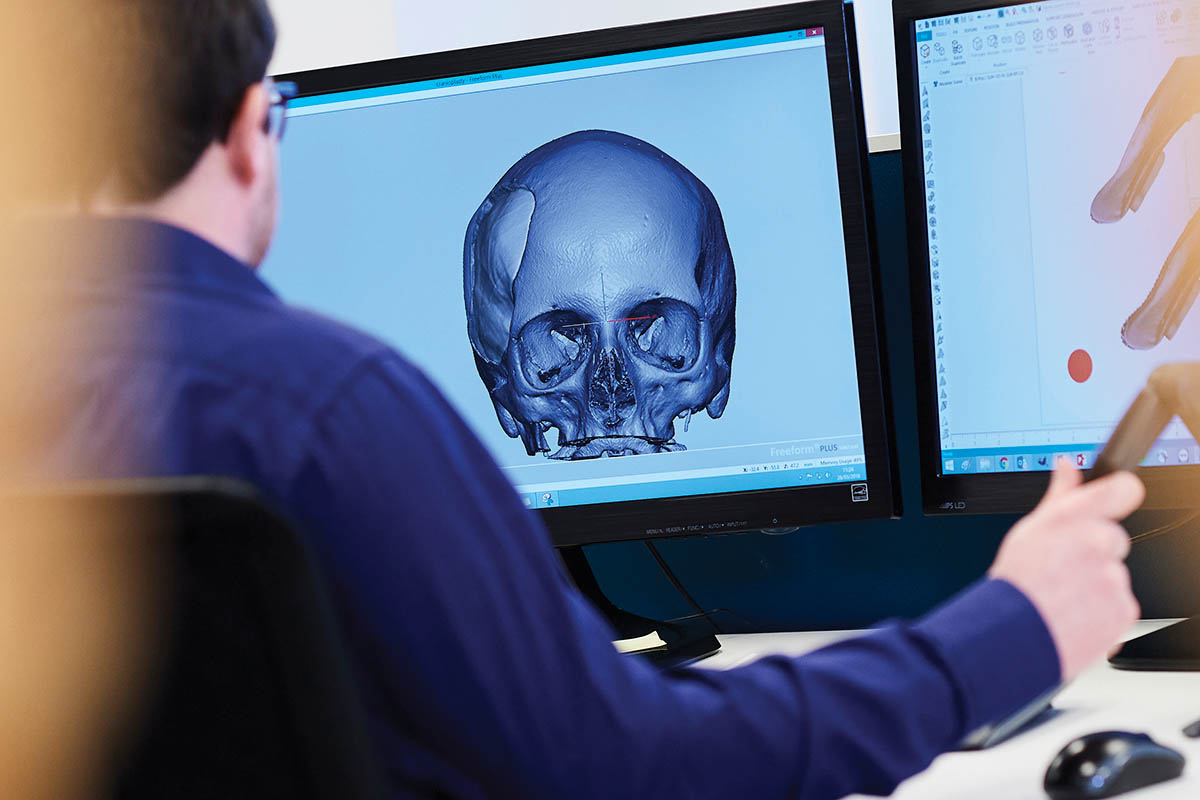

“CAD/CAM stands for Computer-Aided Design and Computer-Aided Manufacturing,” explains Maurice Mommaerts, Belgium’s reference in the field of facial surgery and founder of CADskills. “It means that an object is designed with a graphical software first and that it is created with the help of computers afterwards. This can happen in many different ways. Most common is the CNC technique (or, Computer Numerical Control). Here, a set of computer-controlled tools mill and turn objects into the right shape in no-time.” Yet, while CNC is a trusted method used by the lion’s share of implant manufacturers, it also has some disbenefits. In the milling process, plenty of metal goes to waste, which is both an economical and environmental waste. Furthermore, CNC is a means of mass-production. So, it does not lend itself to the creation of one-of-a-kind items.

Professor Mommaerts. Photo: MVIER- SBS Belgium

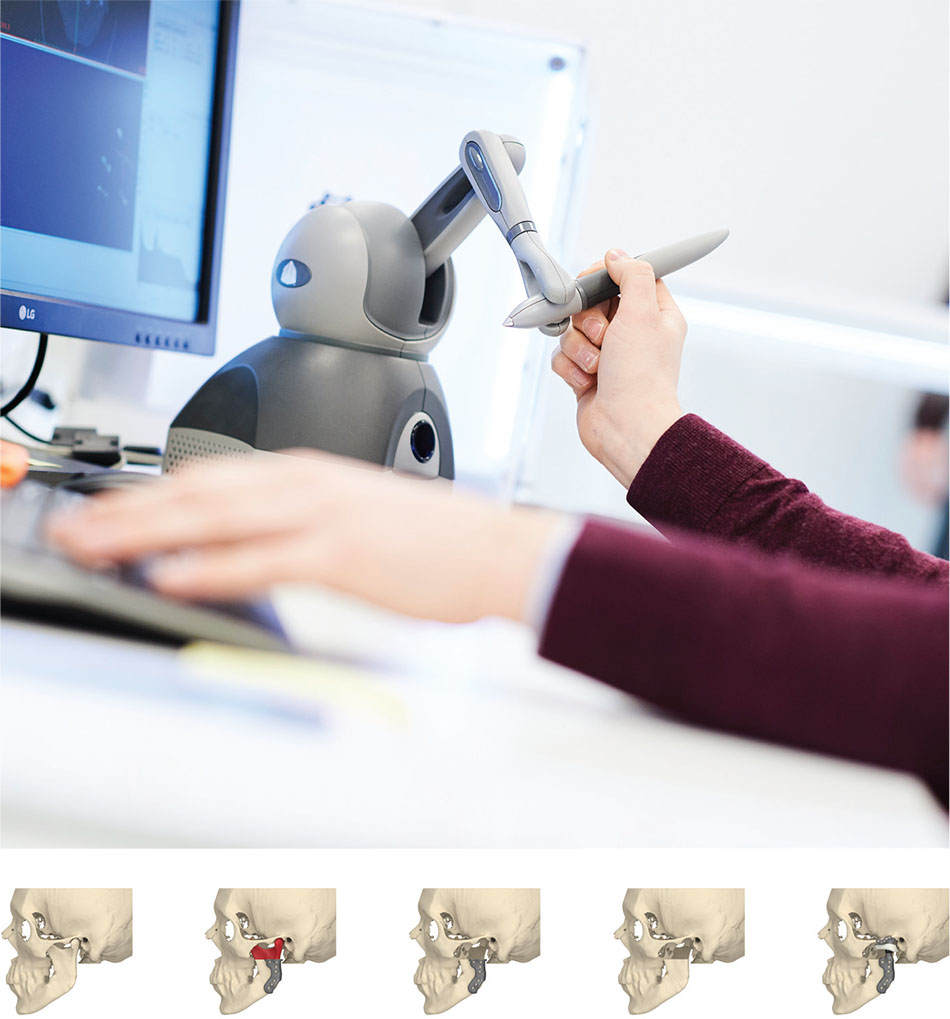

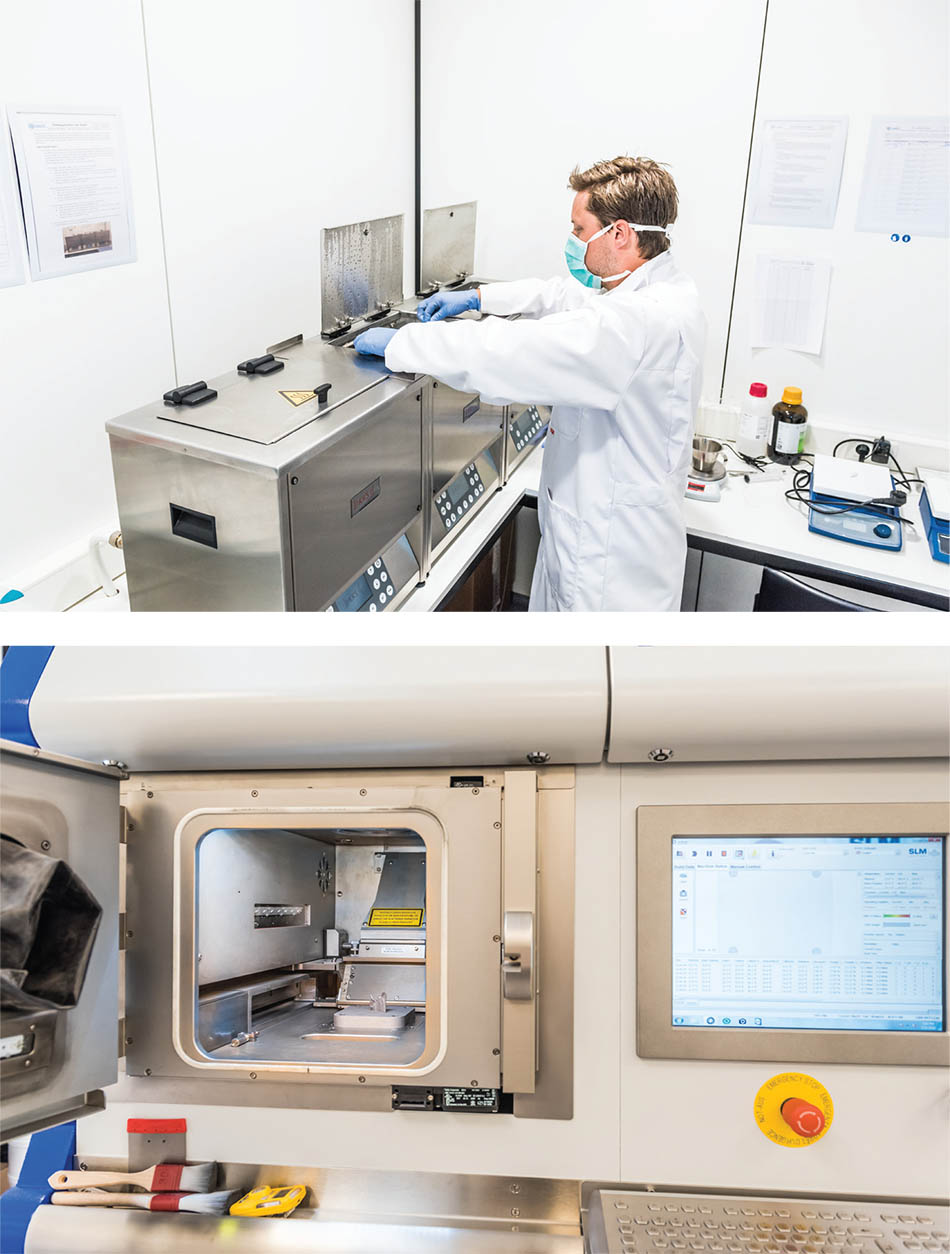

With its focus on custom-made implants, CADskills, therefore, creates its implants by means of additive manufacturing; or 3D-printing, as it is commonly known. “Here, an exact laser melts the object out of a bath of metal powder. The powder that doesn’t get melted can be used again the next time, so very little goes to waste.” This process is slower than CNC and requires quite a bit of manual assistance, but it allows CADskills to create unique implants that fit the customers’ needs perfectly. “We can even create objects that are impossible to manufacture with CNC. If you, for example, want a hollow space within the prosthesis, we can print it that way. You just need to foresee a small hole to remove the excessive metal powder through. Before, creating these was more complex and less durable.”

‘Biofunctionalisation is vital’

Although major leaps have been made in the field of additive manufacturing, it still isn’t quite as precise as CNC. Where the latter generally is exact up to 0.01 millimetres, the former’s precision is only guaranteed up to about 0.1 millimetres. “To resolve this issue, our technicians complete our implant we produce with manual finishing, if necessary. This way, the result is precise up to 0.02 millimetres – about as good as the classic CNC implants.”

Furthermore, every device that leaves the CADskills atelier receives a finishing to optimise it for its specific use. Its’ expertise in polishing, micro-shot peening, acid etching and other finishing techniques is what makes its implants stand out. “Biofunctionalisation is vital in our sector,” explains Mommaerts. “Both on a macro level as on a micro level. The former makes sure that an implant doesn’t only look like the original object but also acts in the same way.” Micro biofunctionalisation, on the other hand, zooms in on the surface of the implant. For the body to recognise it as endogenous, its texture must strongly resemble the original one. If not, the consequences can be severe. “In some cases, overly smooth implants are far from ideal as they allow bacteria to live in the microscopic layer of liquid between the body and the device. Other implants do require a high grade of polishing.” CADskills, therefore, gives every prosthesis the ideal surface for its use.

In terms of materials, CADskills settles for nothing less than the best. It solely works with the purest medical grade titanium alloy around – a very suited material for the manufacturing of implants. “Many stock implant factories also use chrome-cobalt, but we intentionally don’t do so. As the use of this material results in a significantly higher chance of rejection, we avoid working with it.”

A perfect fit

Yet, it is not only the patient who benefits from using CADskills’ custom-made implants. Also, hospitals and surgeons benefit from using them. “When using traditional stock implants, a surgeon has to use the model that fits best. Yet, implanting it will probably still be a bit of a puzzle for which small pieces of bone have to be removed. If the part is custom-made, however, the prosthesis will fit in perfectly, reducing the actual surgery time to a bare minimum.” As the waiting lists of many operation theatres grow longer by the day, reducing the average operation time benefits the hospital, the patient and the surgeon.

Professor Mommaerts. Photo: MVIER- SBS Belgium

Another, not to be underestimated perk, is the psychological impact these custom-made implants have on the patient. “Knowing that an implant is designed and manufactured for them specifically, gives patients a feeling of rest. It is one less thing to worry about in that stressful period of their lives.” Yet, this perfect fit also has its physical perks. Research shows that stock cheekbone implants cause 15 per cent more wear to the surrounding bones than the original bone would have done. With custom-made prostheses, you don’t have this problem.

Change the medical sector

Despite common beliefs, a custom-made implant doesn’t even have to be that much more expensive than a mass-produced one. Of course, its production has a higher price tag, but its simple distribution chain is quite the penny-saver. “A high percentage of the price you pay for your stock prosthesis goes to its distributors. At CADskills, we invest the entire budget in the creation of the implant itself. So, you get better quality for your money.” As the creation process is entirely digital, CADskills can even assist you from a distance. Surgeons from all over the world can just send the CT data of the patient and some specific instructions to the Belgian firm, after which they design and create the implant and send it to the hospital.

As an innovative company, CADskills is always looking for the right craftsmen to join the ranks. As precision and safety is key in the sector, a designer can only create up to 65 implants per year and also the CAD/CAM technicians need time to deliver work of the highest standard. “Today, we produce about six different products, all smaller parts like jaw replacements, skull implants and wrist-bone replacements. In the meantime, we are also developing seven others. We notice that more and more companies, investors and universities are interested in what we do and see the opportunities that it creates. This allows us to expand our domain and also focus on elbows, shoulders, hands and more, as well. We really believe in what we do and how it will change the medical sector. And with the right talent in our team, we might just become Europe’s leading custom implant manufacturer.”

Subscribe to Our Newsletter

Receive our monthly newsletter by email